Coming Soon to a Filling Station Near You: Biofuels, The Next Generation

Bales of corn stover (stalks, leaves, husks, and cobs) in a field in York, NE, after harvest. Corn stover and other harvest leftovers such as wheat straw or perennial grasses such as switchgrass are promising biomass crops for conversion to biofuels. (Photo by Wally Wilhelm, D816-1)

As climate change heats up, so does the race to develop alternative non-fossil-based fuels. Scientists with the Agricultural Research Service (ARS) are taking that quest to a new level, beyond the food quality-based ethanol that’s been a long-time focus.

“[Our] project looks at potential methods to bridge the gap between existing biofuel production facilities and second-generation biofuels,” said Ryan Stoklosa, chemical engineer at the ARS Sustainable Biofuels and Co-products Research unit in Wyndmoor, PA. “This includes looking at ways of integrating cellulosic feedstocks into existing corn ethanol facilities.”

Cellulosic feedstocks include crop and wood residue from trees, dedicated energy crops (those not farmed for food), and other wastes. Each contain cellulose, hemicellulose, and lignin, all of which play a role in the biofuel conversion process.

Researchers are also finding ways to use cellulosic feedstocks that can be upgraded to hydrocarbons for sustainable aviation fuel, as well as how to produce additional value-added products from these “second-generation” feedstocks. Stoklosa said that co-products (secondary goods generated during the manufacturing process that can be sold or reused profitably) are particularly important to many biofuels because they can provide additional revenue and decrease the overall production cost.

The United Nations predicts the global population will surge to 9.7 billion people by 2050. That’s a lot of mouths to feed, so it’s important for scientists to create more uses for non-food agricultural products, such as unused corn stalks. Using marginal land can also be important for growing dedicated non-food biofuel crops, Stoklosa said.

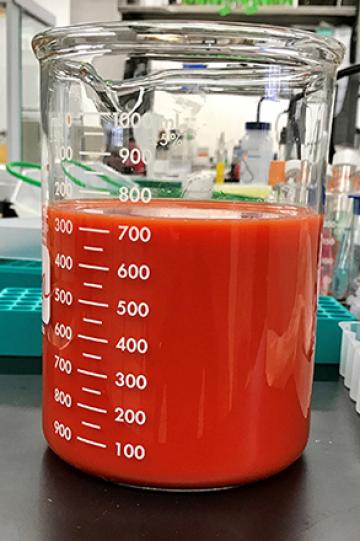

A sample of cultivated Phaffia rhodozyma using fermented sugars from a biomass crop; the color of the yeast is due to the organism's production of astaxanthin, a red pigment often used as a feed supplement for farm-raised salmon. (Photo by Ryan Stoklosa, D4743-1)

Further, the research team is investigating the potential of industrial hemp as a biofuel crop. Hemp is a fibrous crop and makes a good biofuel feedstock due to its short cropping period, high plant biomass yields, low fertilizer and water requirements, and high carbon-sequestration capacity. “Our group is researching hemp on multiple fronts, including how it responds to chemical pretreatment, recovering sugars for fermentation to produce a platform chemical, and characterizing the recovered lignin,” Stoklosa said.

The new biofuel feedstocks don’t contain sugars that are as “easy” to convert as corn, soy, sorghum, and other food-based crops. Rather, the grasses, straw, wood pulp, and other second-generation materials must be pretreated to collect the sugar that’s locked behind the stiff structural plant cell walls.

Stoklosa explained that plant biomass, whether it is an agricultural residue, such as the stalks after corn harvest or woody biomass in the form of trees, has complex physical and chemical structures in their cell walls that impart structural integrity. When exposed to various pretreatment methods these components deconstruct into individual sugar units for cellulose and hemicellulose, or aromatics for lignin. The released sugars are then fermented by yeast or bacteria into an actual biofuel, such as ethanol, or to a different chemical that can be upgraded to a fuel in a later process.

Even after recovering the sugars needed for fermentation to biofuels, Stoklosa’s team isn’t done with what’s left of the feedstock. In some cases, corn is turned into value-added materials like distiller’s grains for use as cattle feed or pulverized sorghum stalks (called bagasse) is returned to the fields as a soil amendment or turned into charcoal briquettes. Another use is recovering the sugars from pretreated bagasse and performing a fermentation with yeast to create astaxanthin, an antioxidant with red pigmentation that is commonly used to supplement the diet of farm-raised salmon.

In other cases, biofuel co-products are reused within the bioprocessing system.

“In a broad sense, ‘co-products’ are additional chemicals that can be generated from either unutilized plant biomass or waste during the production of a biofuel,” Stoklosa said. These co-products, being produced in-house, can reduce the overall cost of biofuel production.

“Improving lives is really the primary goal,” Stoklosa said. “Producing an environmentally beneficial fuel that brings improved economics to the rural economy and broadens the market opportunities for agricultural products will result in the overall benefit of the American people.” – by Scott Elliott, ARS Office of Communications

Also in our biofuels series: