Bringing Your Food Full Circle

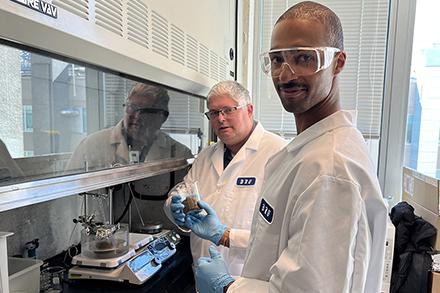

ARS research chemist Gabe Patterson hands a container of nanocellulose material to project leader Jim McManus. The brown, fibrous material is the result of a novel process their team has developed to transform organic waste into a high-value product with many applications, from cardboard boxes to food packaging. (Photo by USDA ARS)

The moment you toss your leftovers into the garbage may be the last time you think about them, but it’s far from the last time they will affect you. When the garbage truck leaves your home, the organic matter you threw away is just beginning a journey that will take it through municipal transfer stations and, usually, to a landfill. There, it will slowly degrade into methane, a planet-warming greenhouse gas that is 84 times more powerful than carbon dioxide.

Over the years, scientists have tried to develop uses for organic waste that divert it from the landfill – perhaps as compost, or biofuel. Now, though, a unique opportunity has prompted them to look for other, potentially better, options. ARSX is an annual competition that asks ARS scientists to propose innovative, high-risk ideas that cross disciplines and break boundaries to solve our most pressing challenges. The 2022 theme, "Innovations for a Circular Economy in Agriculture," focused on “developing regenerative processes and closing gaps in existing loops [to] use our natural resources more efficiently.”

One of three winning projects, “Universal Waste Conversion for a Circular Economy,” succeeded by proposing a new industrial process that will transform organic waste into nanocellulose, a fluffy fiber that can be used in multiple products. To maximize the chances that their ideas would reach the marketplace, the researchers partnered with business leaders already working in the area. Dane McSpedon, CEO of Hughes Energy, explained why he got involved:

“15 percent of methane emissions globally are from rotting organic matter in landfills. Our process essentially gives organic material a second life. We put it into other products that displace the need for fossil fuels or cutting down trees.” In essence, he said, the group is “turning a problem into a product.”

One of the first products the group plans to use nanocellulose for is cardboard boxes. They believe that it could replace existing petrochemical-based products that line cardboard, making it lighter and firmer. With further work, the nanocellulose could also be a component of other products, like single-use paper plates and food packaging liners. That change could have real ramifications for human health.

Municipal solid waste fiber following the Hughes process. Additional processing will transform it for use in a variety of consumer products. (Photo by USDA ARS)

“There’s a class of hazardous chemicals , called PFAS, where very low levels can cause serious health issues like cancer and reproductive toxicity,” said William Hart-Cooper, a research chemist at the ARS Western Regional Research Center (WRRC) and one of the project team members. “PFAS have traditionally been used to coat biodegradable products like disposable plates. Nanocellulose could replace that type of chemical, and we can make it from garbage.”

While nanocellulose materials have been around for some time, the ARSX team developed an entirely new production process, making it easier to transform organic waste into the final product. The process breaks down the organic material using a steam autoclave, a machine that subjects it to high temperatures and pressure.

“The steam treatment is the only preprocessing necessary for the pre-pulped waste fibers before their conversion into nanocellulose,” said Gabriel “Gabe” Patterson, a research chemist at WRRC. “Compare this to existing nanocellulose synthesis processes requiring the harvest, transport, size reduction, and cellulose purification of raw plant materials residues. We anticipate that the Hughes system can both reduce economic barriers to nanocellulose production and mitigate greenhouse gas emissions from landfilling municipal solid waste.”

In the end, the result should be a win for the businesses that get involved and for consumers who get healthier products and, most importantly, fewer climate-warming emissions.

“The really big thing is we’re reducing methane emissions, and stopping forests from being used, so they’ll still be there to trap carbon,” said James “Jim” McManus, a research scientist at WRRC and the project leader. “We’re really making the world a better place, that’s what we want to do with the project.” – Kathryn Markham, ARS Office of Communications