Saving The Earth One Container at a Time

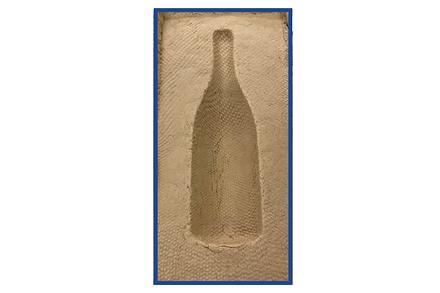

Biodegradable fiber foam wine shipper designed as a replacement for plastic foam wine shippers. (Photo by Greg Glenn, ARS)

Single-use plastic containers are everywhere: Products like toothpaste, shampoo, condiments, carryout containers, and even water nearly always come in packaging that we use once and then throw away. These single-use containers fill up our landfills and can stay many years, with some plastics lasting hundreds of years in a landfill. If not disposed of properly, plastics can litter our landscapes and spill into our oceans. Although these items may seem convenient for storing our food or products, the effects they have in our environment are devastating. For this reason, researchers are working hard to replace these plastics with materials that are biodegradable.

“Plastics are moisture resistant, grease resistant, strong and lightweight, but the problem is they do not biodegrade,” said William Orts, ARS Bioproducts Research Leader and Acting Center Director in Albany, CA. His team is researching agricultural materials that could replace plastics, while also implementing zero waste agriculture, greenhouse gas reduction, and a circular economy, which is based on knowing where the product will end up, whether it be in composting or a recycling facility. One promising approach is to use corn or sugar sources in the plastic-making process. After conversion, the plant-based matter becomes polylactic acid, a material that works like traditional plastic but is compostable and safer for the environment.

Another approach to eliminating plastic packaging is to use plant-based fiber to create products that are environmentally harmless but provide similar results to plastic. Originally, these fiber containers were made from wood fiber, so in order to make them trees needed to be cut down. ARS researchers developed techniques to make fiber packaging from other materials like crop straws or crop fibers, including wheat straw, bamboo, and cotton. To achieve this, they re-purposed leftover fiber, avoiding waste while turning the material into a pulp that could be pressed into shape.

While this method of making containers has a lot of advantages, like being eco-friendly, there are still details to improve. Typically, plant-based items tend to be frail and not very sturdy on their own, which is why they require additives and binders to make them moisture- and grease-resistant. “Traditionally, many additives have included chemicals that contain fluorine compounds, which are difficult to degrade and can contaminate groundwater and waterways” explained Gregory Glenn, ARS Bioproducts Research plant physiologist in Albany. Another common binder is wax.

“If you have to use wax to try to make the plant fiber material moisture-resistant or grease-resistant, then the wax typically degrades more slowly than the fiber,” said Glenn. “The fiber itself will degrade, in a composting facility, in about 60 days, but depending on what other additives you put in that fiber, it could take much longer.”

ARS researchers continue to seek better solutions, including a way to replace polystyrene foam or Styrofoam by making fiber foam. In the meantime, consumers can do their part by discarding the products we buy correctly in the recycling or compost bin and using lower-plastic or plastic-free products that prevent the problem of plastic pollution in the first place. — By Olga Vicente, ARS Office of Communications

You May Also Like