Thanks a Clot!

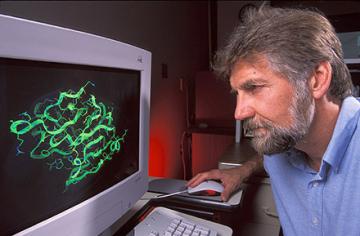

Chemist Vince Edwards examines a computer graphic image of an enzyme model used in the design of cotton-based wound dressings. (Peggy Greb, K10175-1)

ARS cotton research is behind a new blood-clotting gauze

Continuing a tradition of excellence in the textile sciences, Agricultural Research Service (ARS) scientists in New Orleans, Louisiana, have helped develop a nonwoven cotton gauze that could usher in next-generation wound dressings that quickly stanch bleeding and promote healing.

A team led by chemist Vince Edwards at ARS’s Southern Regional Research Center (SRRC) in New Orleans collaborated with H&H Medical Corporation (H&H) of Williamsburg, Virginia, and others to develop the gauze dressing, which is made of greige (raw, unbleached) cotton fiber rather than the processed kind typically used.

SRRC’s pioneering research on the medical uses of cotton dates to World War II, when textile chemist Charles Goldthwait teamed with the commander of a local Naval hospital and his staff to create a semi-elastic, form-fitting dressing that proved superior to those being used at the medical facility. These gauzes were battle tested toward the war’s end, patented by the U.S. Department of Agriculture, and commercialized by industry.

In November 2018, SRRC celebrated another successful collaboration in the form of TACgauze, the latest in a line of trauma-response products sold by H&H for use by military, law enforcement, commercial, and civilian first responders.

Buying Time

According to BleedingControl.org, uncontrolled bleeding (hemorrhaging) is the number-one cause of preventable death in people with a traumatic injury. This can happen in 5 to 10 minutes if severe blood loss from the injury site isn’t slowed or stopped, a state known as hemostasis. High blood loss can also lead to hypothermia, multiple organ failure, and infection.

In an Army study that examined combat casualty deaths in Iraq and Afghanistan from 2001 to 2011, uncontrolled blood loss was the leading cause of death in about 90 percent of cases where an injured soldier could have survived—had it been possible to evacuate the soldier for emergency care.

In recognition of that critically short window, H&H has focused on creating hemostatic gauzes and other trauma care products that are easy to carry and use, affordable, reliable, sterile, long lasting, and effective under a wide range of environmental conditions or situations—battlefields, accident sites, mass-casualty events, or remote locations.

Scientists at the USDA ARS Southern Regional Research Center collaborated with H&H Medical Corporation to develop TACgauze, for use in wound dressing to reduce blood loss. It is made of greige (raw, unbleached) cotton fiber, which is very absorbent. (Peggy Greb, D4084-1)

Natural Is Key

The product of a joint research-and-development effort, TACgauze builds on more than a decade of research by Edwards and colleagues that includes devising methods to evaluate the blood clot-promoting properties of both greige cotton fiber and the fabric made from it.

Unlike processed cotton, greige fiber isn’t scoured and bleached. This leaves its natural store of lipids, waxes, and pectin intact in the outer cuticle and primary cell wall, which is largely made of crystalized cellulose. All these components contribute to greige cotton’s absorbency and softness, notes Edwards, who is with the SRRC’s Cotton Chemistry and Utilization Research Unit.

Edwards identified the cotton fiber cuticle’s role in stimulating the body’s production of fibrin and other blood-clotting agents. He and his team did this by adapting a technique used in hospitals to assess patient clotting profiles. Studies with Virginia Commonwealth University (VCU) assessed the overall clotting properties of fabric made from the fiber using animal models. They showed that when made into a gauze used to wrap or pack wounds, greige fiber performed as well as standard dressing gauze.

Another plus: greige cotton gauze also released small amounts of hydrogen peroxide, which may play a role in cell signaling, movement, and proliferation at wound sites. This and other findings related to greige cotton’s wound-healing properties were reported by the SRRC-VCU team in a series of papers published in the Journal of Functional Biomaterials and Wound Repair and Regeneration.

In trials, the nonwoven greige cotton gauze was 33 percent lighter and 63 percent more absorbent than the currently used woven, crinkle-type gauzes made from processed cotton fiber. During the trials, the nonwoven cotton gauze also triggered blood-clotting more quickly than the bleached cotton gauzes and shed fewer fibers, which can mean less lint ending up in wounds.

Cross-cutting Collaboration

Edwards credits T.J. Beall Company’s proprietary fiber-cleaning technology with preserving the clot-promoting properties of greige cotton and, in particular, the company’s trademarked TrueCotton brand. T.J. Beall also collaborated with the SRRC group in forming the greige cotton into a pliable, nonwoven gauze using a fabrication procedure called spun lacing, which entangles the fibers.

H&H President Paul Harder says his company has received interest in evaluating TACgauze from both military and civilian sectors. The feedback so far has been encouraging, adds Joe DaCorta, H&H Vice President. “They like the look and feel of it,” he says.

DaCorta first learned of greige cotton’s potential after reading a scientific paper Edwards’s group published in 2014. He quickly notified Harder, who was keen on moving H&H towards using U.S.-sourced fibers to ensure its trauma-care products satisfied the tenets of the Berry Amendment, a 1941 law limiting the military’s purchase of certain goods to those of U.S. origin. The details of that paper, says Harder, “told a story that we liked and matched what we were doing.”

Spin-Offs

The resulting collaboration didn’t end with TACgauze’s commercial launch, however. The group has its sights on combining the new gauze with functional fabric finishes and treatments, such as those containing antimicrobial, hemostatic, and wound-healing agents. They’ve also made good progress on a prototype gauze that owes its antimicrobial properties to new, nontoxic, and inexpensive chemicals.

Harder says the prototype gauze has sparked interest for use in “prolonged field care” scenarios, where unavoidable delays in evacuating an injured soldier may necessitate advanced wound-care measures to protect and preserve damaged tissues until transport is possible.

For his part, Edwards feels the partnership with H&H, VCU, and T.J. Beall exemplifies how diverse groups can leverage their resources and expertise towards a common cause and a clear public benefit: saving lives.

The collaboration also supports SRRC’s overarching mission of investigating new, value-added uses for agricultural commodities, like cotton, that will not only benefit U.S. growers, but also processors and consumers—a mandate the ARS center has fulfilled since its establishment in 1938.—By Jan Suszkiw, ARS Office of Communications.